Predictive Maintenance in Oil & Gas

Why IoT Connectivity Is the Missing Link

In the oil and gas industry, equipment downtime doesn’t just disrupt workflows—it burns through budgets. With unplanned outages costing millions per incident, predictive maintenance has emerged as a smart, scalable solution. But while the value is clear, adoption is still lagging behind.

Why? Because most operations don’t have the connectivity infrastructure in place to power real-time insights. That’s where IoT, and the right industrial connectivity partner, comes in.

In this blog, we’ll break down:

- Why predictive maintenance matters more than ever

- What’s holding industrial teams back

- How IoT-enabled connectivity can unlock serious uptime and ROI

Why Predictive Maintenance Matters

Harsh environments, remote assets, and complex machinery make the oil and gas industry the perfect candidate for predictive maintenance. Rather than relying on calendar-based or reactive maintenance strategies, predictive systems monitor asset health in real time and take action before failure occurs.

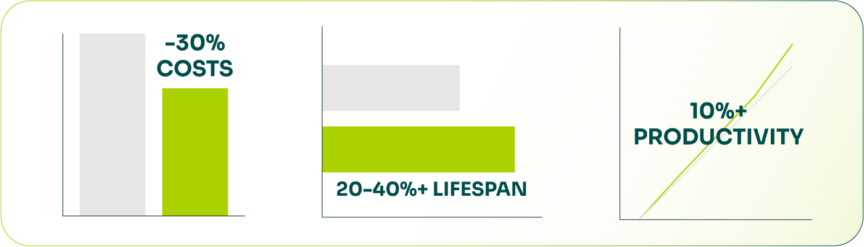

Here’s what that can mean:

- 30% lower maintenance costs

- 20–40% longer equipment lifespan

- 10%+ increase in productivity

- Millions in savings by avoiding unplanned downtime

These aren’t just stats; they’re potential game-changers for field operations and bottom lines. From compressors and pumps to pipeline valves and SCADA systems, early detection of wear, overheating, or vibration abnormalities can prevent catastrophic failures and the costly cleanup that follows.

What’s Holding Predictive Maintenance Back?

If predictive maintenance delivers such strong returns, why hasn’t it been widely adopted across the industry?

Here are five of the biggest roadblocks:

- High Upfront Costs

Outfitting assets with industrial-grade sensors, integrating analytics platforms, and training staff can require a significant capital investment, especially for mid-size operators. - Legacy System Fragmentation

Many oil and gas sites still rely on legacy SCADA and OT systems that weren’t built to share data, making it harder to capture and act on insights in real time. - Lack of Skilled Resources

Predictive maintenance isn’t just plug-and-play. It requires cross-functional collaboration—something many companies are still building. - Connectivity Challenges

From offshore rigs to remote pipeline stations, reliable connectivity is often the missing piece. Without constant data flow, predictive models are blind. - Cybersecurity Concerns

Bringing real-time monitoring online can expose sensitive operational data. Security must be built in from the start.

How IoT Connectivity Enables Predictive Maintenance

The foundation of every predictive maintenance strategy is reliable, real-time data—and that’s where IoT connectivity shines. With industrial-grade SIMs, secure network architecture, and powerful management platforms, operators can:

Monitor Assets in Real Time

IoT sensors continuously capture vibration, temperature, flow rate, and pressure data. This allows teams to track changes as they happen and catch red flags before failure.

Reduce Downtime with Instant Alerts

Cloud-based dashboards and AI tools can issue automatic alerts when readings fall outside normal thresholds, helping crews act before problems escalate.

Prioritize Maintenance Based on Risk

Instead of servicing everything on a fixed schedule, teams can prioritize assets based on actual usage and wear, saving time and reducing unnecessary labor.

Improve Safety & Compliance

IoT-powered predictive maintenance helps prevent hazardous failures in high-risk environments, keeping people and infrastructure safer while staying compliant.

Connectivity: The Critical Layer

Even the best predictive tools can’t function without reliable, real-time connectivity. That’s where Solve Networks comes in.

Solve delivers purpose-built IoT connectivity for industrial environments. Our platform enables:

- Always-on SIM coverage, even in remote or rugged environments

- Multi-carrier failover, so your data doesn’t drop when you cross coverage zones

- Secure, scalable connectivity, with private networking options and static IPs

- Real-time usage monitoring, alerts, and API access via our Connectivity Management Platform

- Expert support, from engineers who know industrial IoT inside and out

Predictive maintenance isn’t just a buzzword—it’s a powerful, proven strategy to cut costs, increase uptime, and stay ahead of mechanical failures. But it only works when every piece of the puzzle fits.

IoT sensors, AI models, and analytics tools all rely on a simple truth: if you can’t connect it, you can’t protect it.

Solve Networks helps oil and gas operators overcome the last-mile connectivity challenges that stall predictive maintenance strategies. Let us help you build smarter, safer, more reliable operations—today and into the future.

Talk to our team to learn how we can connect your data, your devices, and your team for better performance and fewer surprises.